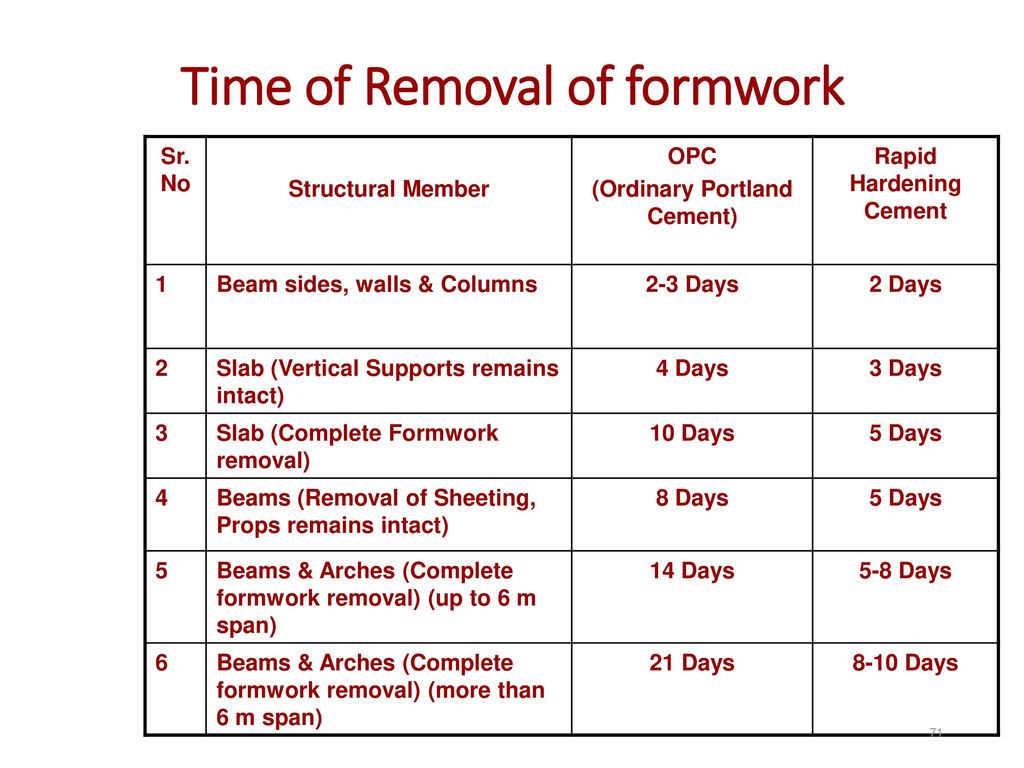

RE Minimum Stripping Time for Slab Forwork NS4U (Structural) 17 at early ages concrete modulus is not proportional to strength gain Modulus gain lags strength gain So, beware of higher Removal of Formwork In normal circumstances (generally where temperatures are above 0 C), and where ordinary cement is used, forms may be struck after expiry of following periods Type of Form Removal Time Period Walls, columns and vertical sides of beams 24 to 48 hours as may be decided by the engineerincharge Slabs (props left under) 3 days Beam#SlabConstruction #SuspendedSlab #AmazingWorker #TraditionalTimberFormwork#SteelRebar #Slab#ConstructionWorkProcess👇 SUBSCRIBE TO Aperture Of Construction Y

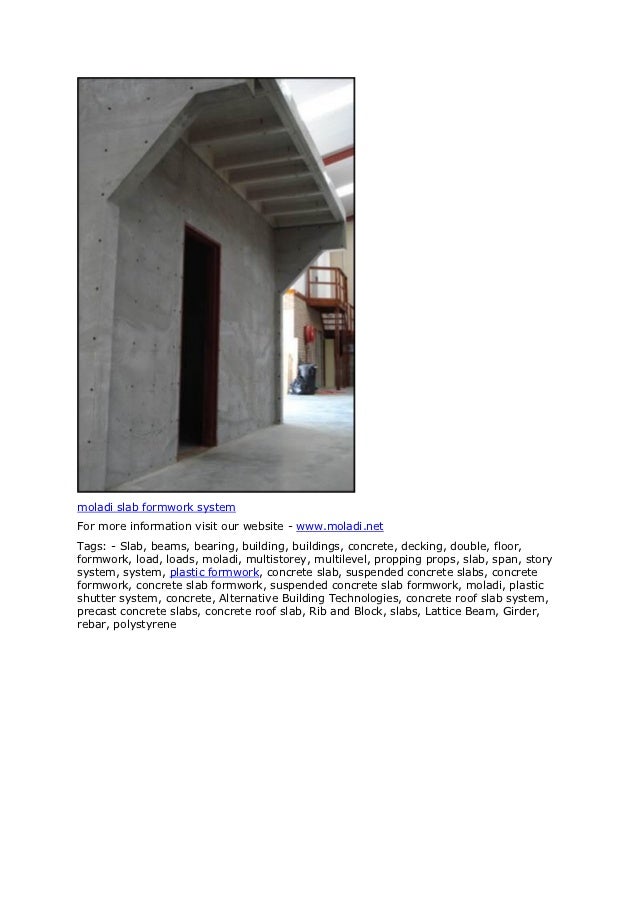

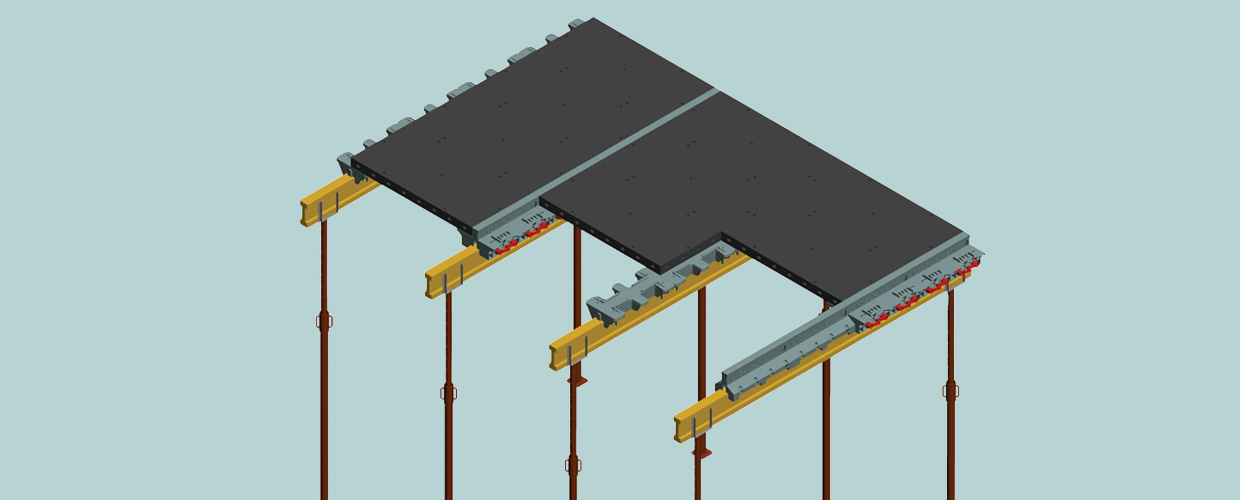

Suspended Concrete Floor Slab Formwork System

Suspended slab formwork removal

Suspended slab formwork removal-One wall of a minimum of 18 metres high by 10 metre long;Removal Release Dropheads with a hammer These quickrelease Dropheads allow for removal of framing members as early as one day after the pour in accordance with ACI 301 section 2325 Remove Main Beams and Secondary Beams and place them in the barellas These beams can be cycled to floors above, requiring less equipment overall

Formwork Cpccca3019a Erect Dismantle Formwork For Suspended Slabs Columns Beams And Walls Ppt Download

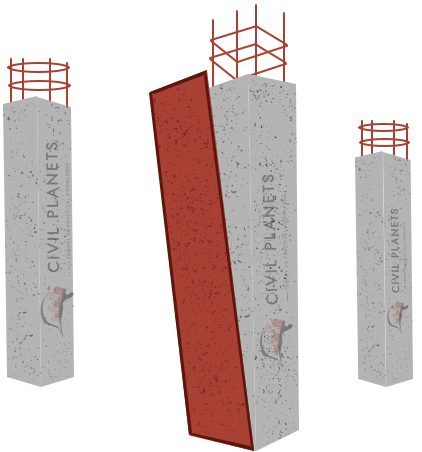

Two different types of columns with a specified formwork system at a minimum Concrete slabs are built in situ using formwork, which is a box that holds the concrete mixtureIf the slabs will be reinforced, the rebar must be placed in the formwork To ensure that concrete has fully set and the reinforcement is enclosed, plastic tipped metal or bar chairs can be used This will keep the rebar from being pushed into the foundation For a groundFor suspended slabs, the formwork will be in the shape of a tray, with supporting slabs underneath After the concrete sets the formwork and supports are removed Suspended S labs Are Widely Used In The Construction Industry Due to it's many advantages it speeds up construction as well as saves on costs Videos Are Under Construction They Will Be Uploaded

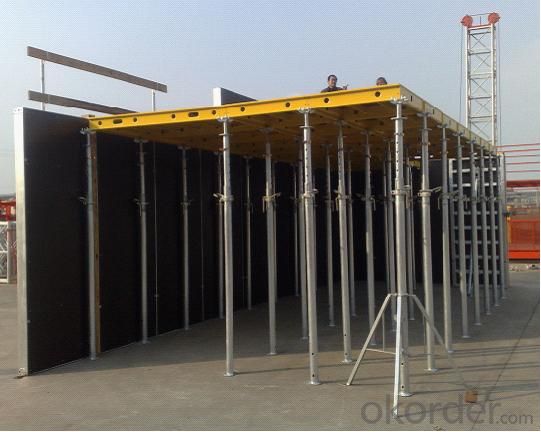

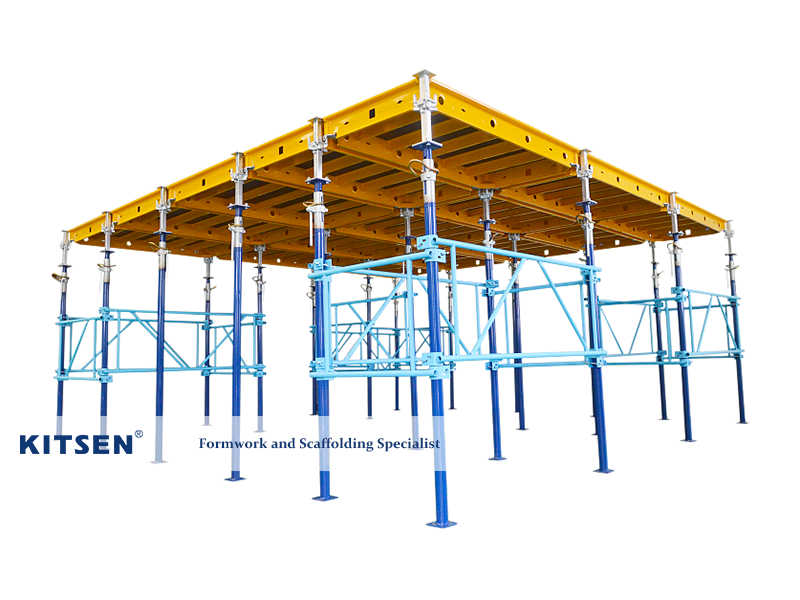

For the construction of structural floor slabs formwork shall be used as per shop drawings and manufacturer's recommendations The PD 8 Shoring Tower & cuplock system will be erected on a load bearing horizontal base The assembly of the shoring tower will be made horizontally and a crane is necessary for erecting PERI FORMWORK SYSTEM Base Area and First Level Place twoChapter 4—Strength adequacy of concrete slabs and formwork, p 3472R8 41—Earlyage concrete material strength development 42—Construction load factors 43—Earlyage capacity of concrete slabs 44—Serviceability requirements 45—Formwork adequacy Chapter 5—Construction examples, p 3472R10 51—Twoway slab construction 52—PosttensionedSuspended slabsFor a suspended slab, there are a number of designs to improve the strengthtoweight ratio In all cases the top surface remains flat, and th

Overview of the project Cassaform were engaged to provide engineering design, certification, and supply of a modular formwork system to form the realigned section of the Caulfield to Dandenong railway to facilitate the existing level crossing removal The Cassaform P300 Modular Formwork System used had to be fast, lightweight, and costOur offering includes engineering services, slab installations, formwork, in situ slabs, Echo rib & block slabs, concrete rib & block slabs, coffer slabs, concrete staircases & ready mix concrete We have enough equipment & formwork to handle the construction of any concrete slabs in Pretoria from 5 m² to 00 m² in one pour So if you need a competitive price on your next concrete slabOverloading of the formwork during concrete pouring operations Formwork can be constructed to meet a custom design produced by a competent person or a proprietary system can be used in accordance with the manufacturer's recommendations Safe work method statement Safe work method

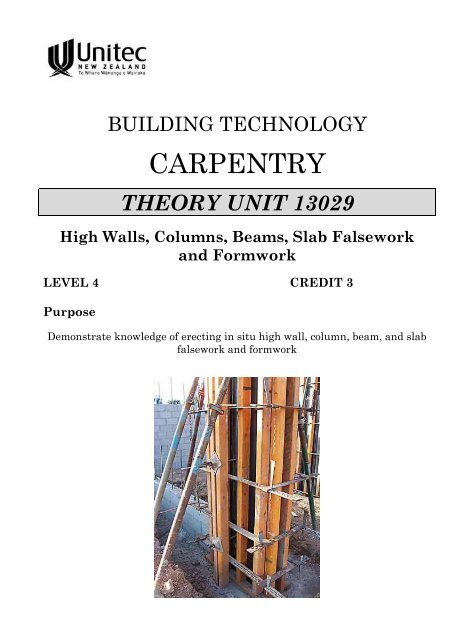

Commercial Formwork Unitec

Video Building Formwork

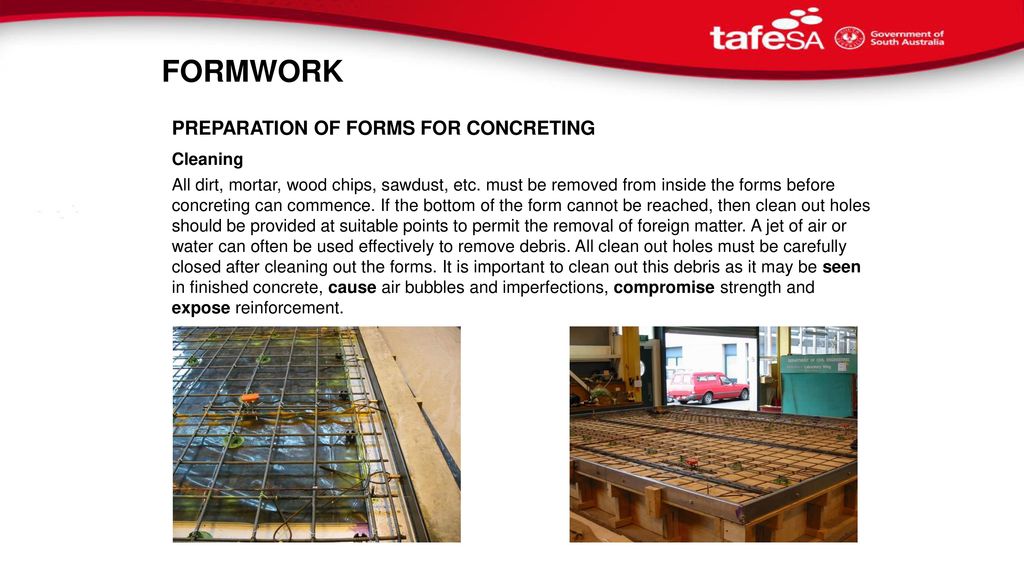

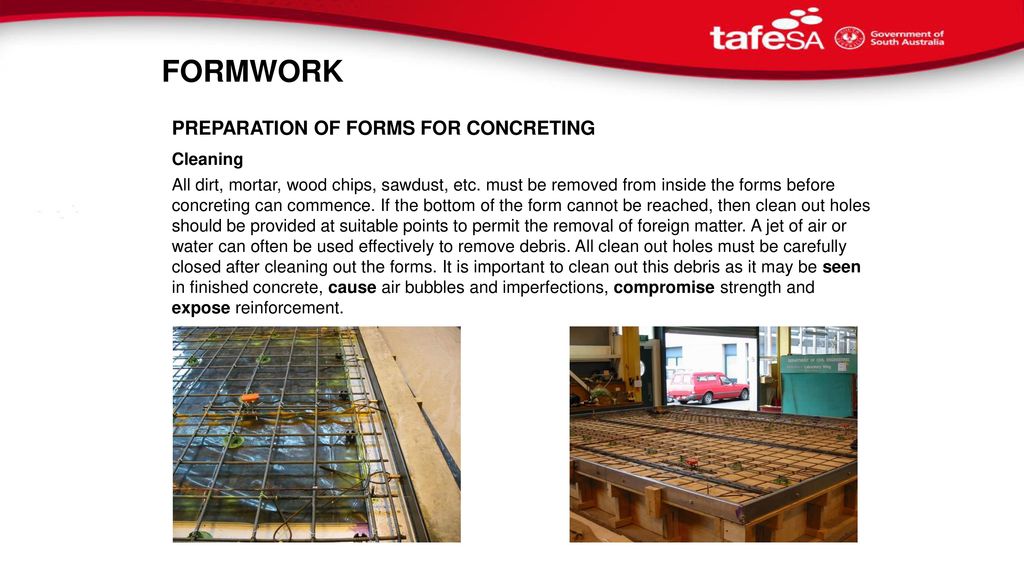

Removal of debris Provide all formwork with special cleanout holes to allow for the removal of sawdust, shavings, and other debris from the bottom of the formwork before the pour begins Formwork Tolerances and variations in alignment Columns Up toFormflex is a temporary works system to facilitate the forming and support to suspended concrete slabs The system concept is to provide a simple straight forward and safe solution for the customer whilst providing a versatile solution for a variety of slab thicknesses and shapes to construct By using a standard 2m x 1m grid the Formflex givesRemoval of formwork before the concrete achieves adequate strength;

Suspended Concrete Floor Slab Formwork System

Suspended Slab Formwork Cassaform Construction Systems

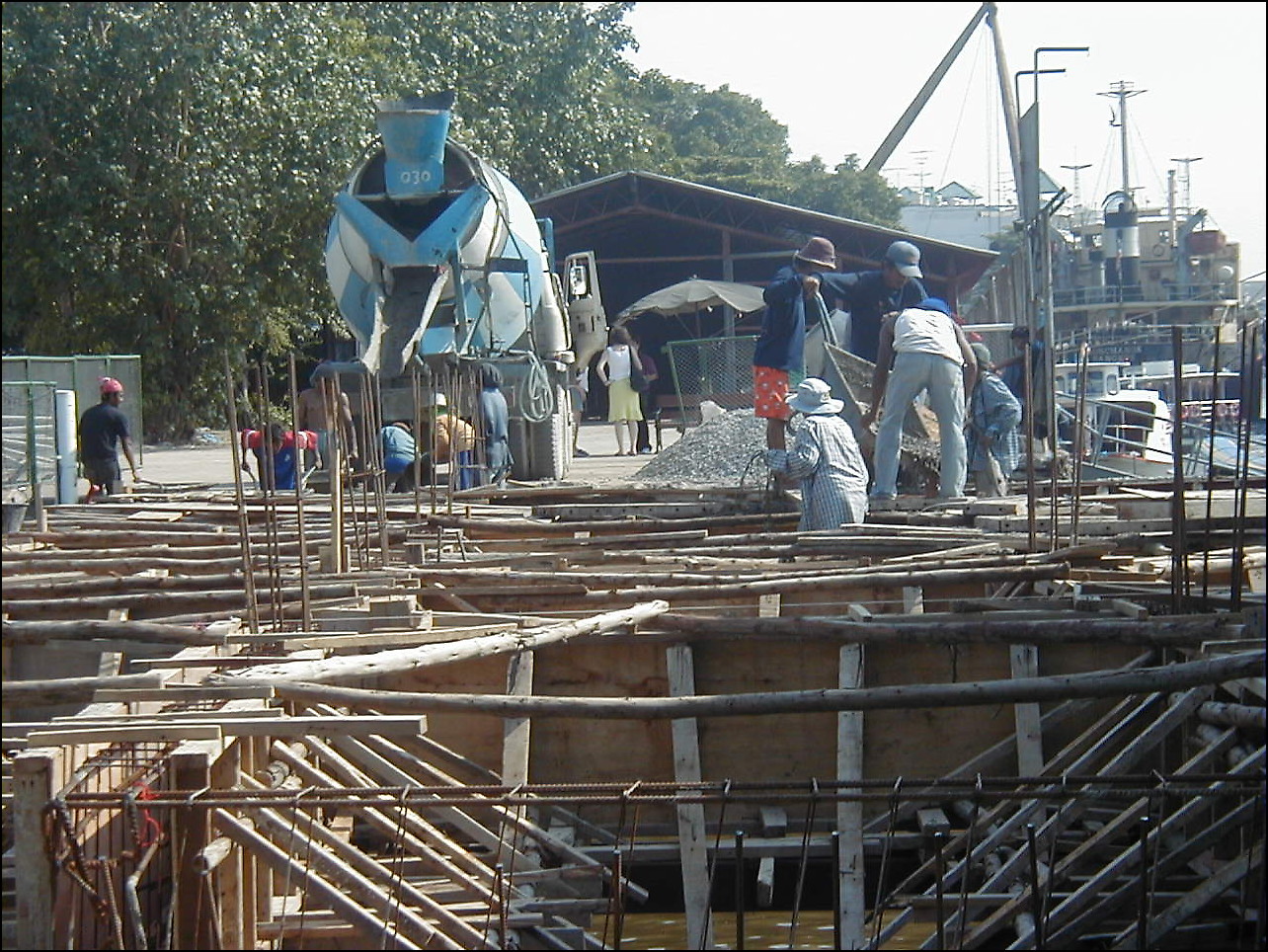

Suspended slab formwork is formed and cast onsite, and this is done with removable or nonloadable formwork s or permanent formwork s that form part of the reinforcement Therefore, to produce a suspended slab formwork, we need precise formwork, which can be selected from two different types Either they have the ability to be removed after Floor slabs Spans over permanent supports less than 10 feet 4 days*** 3 days Spans over permanent supports 10 to feet 7 days** 4 days Spans over permanent supports more than feet 10 days** 7 days * But observe requirements for floor slabs or soffits of joists and beams, if the same forms support them** Half this interval if forms may be removed without#SlabConstruction #SuspendedSlab #AmazingWorker #TraditionalTimberFormwork #SteelRebar #Slab #ConstructionWorkProcess 🔥My Instagram accounthttps//wwwinst

Slab Formwork Mevaflex Meva Schalungs Systeme

Formwork Construction In Structures

Slab formwork (deck formwork) Pantheon dome Schematic sketch of traditional formwork Modular formwork with deck for housing project in Chile Steel and plywood formwork for poured in place concrete foundation History Some of the earliest examples of concrete slabs were built by Roman engineers Because concrete is quite strong in resisting compressive loads, but has Engineered formwork is a type of mold that concrete is poured into to create walls, slabs, columns, and many other types of cement structures Engineered formwork is a metal mold, typically made of steel or aluminum, gives contractors the option to create structures of many different shapes and sizes It is a costeffective alternative to traditional timber formwork;Practical activity for Illawarra Carpentry Students to complete formwork to suspended slabs beams and columns

4 3 Formwork For Concrete Stairs

Slab Formwork Early Stripping Slab Formwork Systems Kitsen

The formwork essentially also provides curing for those surfaces If you strip earlier then you would have to cure those surfaces of the concrete in some other way!Answer (1 of 7) We design one RCC member by assuming certain strength of materials used, mainly conc and steel While designing we adopt a factor of safety and/or load factor based on 28th days of curing of a definite mix of conc cubes Thus any36—Inspection and adjustment of formwork 37—Removal of forms and supports 38—Shoring and reshoring of multistory structures Chapter 4—Materials, p 41—General Reported by ACI Committee 347 Rodney D Adams Samuel A Greenberg H S Lew Kenneth L Berndt R Kirk Gregory Donald M Marks Randolph H Bordner Awad S Hanna Robert G McCracken Ramon J

Large Area Formwork Top 50 By Acrownz Issuu

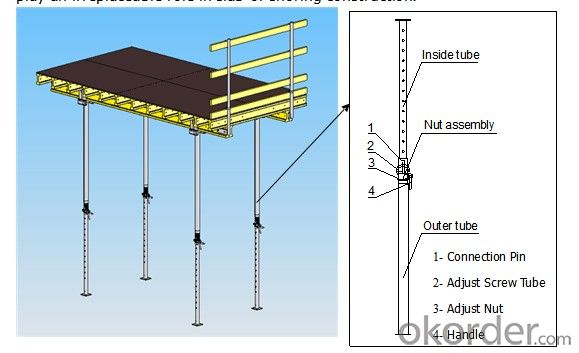

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

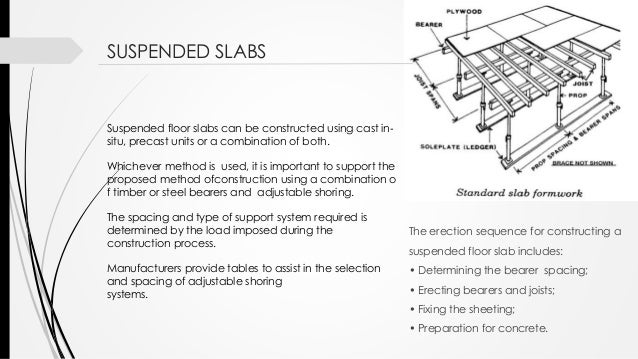

Suspended slab formwork removal Suspended slab formwork removal Removal Time Period Walls, columns and vertical sides of beams 24 to 48 hours as may be decidedA method of constructing a suspended floor is described in which a plurality of beamforming formwork assemblies are located in substantially parallel alignment, the beamforming formworkThe selfweight of the completed concrete slabs is generally assumed in backpropping calculations to be based on a density of 24 kN/m³ for building multistorey flat slab structures When placing the new slab, the falsework and the backpropping should be designed for the new concrete, being "wet", using a density of 25 kN/m² The density generally used on civil engineering structures isOn the right is the slab formwork for a suspended concrete slab to a multi story building, but this system of concrete formwork could just as easily be used on an owner builder house What you see is a series of steel frames with cross braces holding them together They have adjustable screw jacks at the bottom and top The top jacks carry heavy timber bearers, (150 x 100) at say 10

Pier Construction Architecture Is What We Do Home Facebook

Concrete Floor Slab Construction Process The Constructor

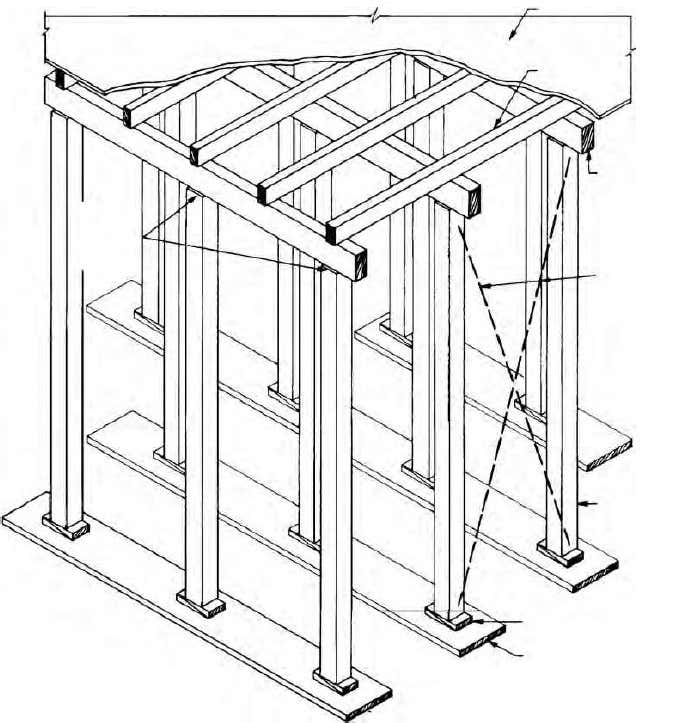

A concrete slab is a common structural element of modern buildings, consisting of a flat, horizontal surface made of cast concrete Steelreinforced slabs, tThe raft or ground level slab is the simplest and most common slab construction technique It is this technique that will be used for Assessment 3, where you will construct the formwork for a slab along the outer edges of the building footprint, Step 6 Raft or ground level slab The following steps are used to construct a raft or ground level slabLogistically, a number of formwork components need to be moved up to each floor before the suspended concrete slabs can be poured Unless this is a precast system, that stage of the project just can't be avoided Wooden boards and plywood panels are transported to the required level of the rising edifice Underneath the formwork panels, temporary beams and frames are

Concrete Slab Abis

Concrete Formwork For Slabs

Do not allow personnel on or directly under any gang form while it is being moved or suspended in air Do not erect gang forms when job site wind conditions prevent safe maneuvering of gangs Assure that all rigging connections are properly made in accordance with safe practices and procedures Formwork should be adequately braced, reanchored, or otherwise secured prior toExample formwork for the floor, floor beam bottom, slab, etc It is a type of formwork that support only horizontal surface In the below image you can see the centring work for slab Staging Material such as wooden bullies, pipes, prop support, coupler, and the cuplock system used to support the framework is called staging Scaffolding A platform provided for workers around theA complete bay of suspended floor slab, and modular formwork systems which are often lighter weight and eliminate the need for tasks like repetitive hammering 3 ULY 14 UDE T FMWORK Types of formwork The safety of workers erecting, using and dismantling the formwork should be considered when choosing a formwork system for a particular job In particular consider

1

Formwork Cpccca3019a Erect Dismantle Formwork For Suspended Slabs Columns Beams And Walls Ppt Download

All floors are suspended floors 5 Figure 2 gives location of loads wp, wb1, and wb2 *Backpropping is defined as propping installed at levels below the slab supporting the falsework It is done to distribute the load applied to the uppermost slab to suitable supports, such as lower slabs or foundations •Obtain approval to strike •Check the safety precautions •Strike according toModulecon's Sure Slab System is a fully suspended concrete slab off ground solution designed for reactive soil conditions Through the ingenuity and collaboration of various patented building products, Modulecon has been able to resolve the major concerns regarding the management of soil conditions for domestic footing and foundation designs The costs associated with theseDoka is a world leader in providing innovative formwork, solutions and services in all areas of construction The company is also a global supplier of wellthoughtout scaffolding solutions for a varied spectrum of applications With more than 160 sales and logistics facilities in over 60 countries, Doka has a highperforming distribution network for advice, customer service and

Deshuttering Time For Slabs Beams And Columns As Per Is Code

Formwork For Decks And Floors Concrete Construction Magazine

The Aluflex system is a high load capacity formwork system for the support and forming of suspended concrete slabs The systems basic components are the Alulight Multiprop, the Aluflex 105 Bracing Frame with primary and secondary beam options The primary beams being secured to the prop heads with steel clips or held in a steel fork headThe formwork serves as a frame for the shape of the concrete, holding the poured material in place as it cures Once the concrete achieves a state of hardness that's capable of supporting its own weight you can remove the forms Removing forms isn't a difficult process, but it is laborintensive It will require the use of a hammer and pry bar, but once you get started the forms just fall away SUSPENDED SLABS Suspended floor slabs can be constructed using cast in‐ situ, precast units or a combination of both Whichever method is used, it is important to support the proposed method ofconstruction using a combination o f timber or steel bearers and adjustable shoring The spacing and type of support system required is determined by the load imposed

When To Remove Concrete Forms How Long Should Concrete Cure Before Removing Forms Deshuttering Time Civiconcepts

Suspended Concrete Floor Slab Formwork System

Kit CPCCCCA3019A NVR Standard 155 1 006 Erect and dismantle formwork to suspended slabs columns, beams & walls Page 1 of 70 CPCCCA3019A Erect and dismantle formwork to suspended slabs, columns, beams and walls Student Learning Resource Student Name _____ Type Title Standard Issue Version Ref Release date Kit CPCCCCA3019A NVR Standard 155 1 006 The most important factor in formwork removal is ensuring the concrete is given the proper amount of time to reach the necessary load strength Size, grade, and temperature all play a pivotal role in determining how early it can be removed Large concrete sections usually strengthen more quickly than smaller ones, but the load bearing needs should also be considered For As already mentioned you can see the formwork removal time for beams and slabs is more comparatively The above mentioned time varies based on the type of cement used SNo Structural Member Time of Removal 1 Walls, columns and vertical sides of beam 2448 hours 2 Slabs ( props left under) 3 days 3 Beam soffits (props left under) 7 days 4 Removal of props

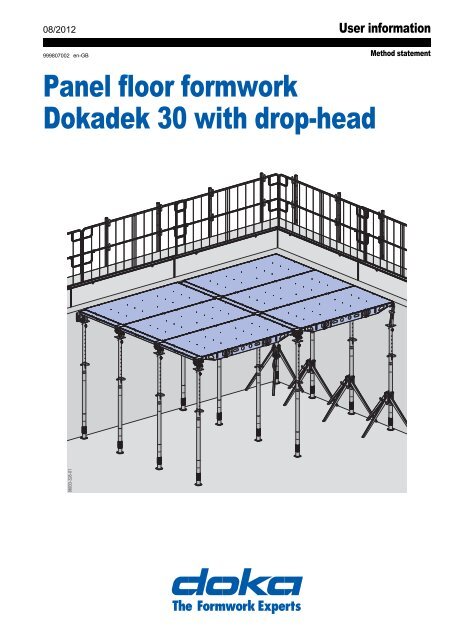

Panel Floor Formwork Dokadek 30 With Drop Head Doka Lietuva

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

H Timber Beam System The MEVA H formwork girder is an engineered composite timber beam, used to construct concrete slabs, wallsand columns It is used for primary and secondary beams in slab construction, including table and flying forms It can be used as walers on wall and column forms, backed by Slimlite soldiers2 Erect formwork 21 Work area is cleared and surface prepared for safe erection of formwork for suspended slabs, piers and shutters 22 Formwork is set out to requirements of plans and specifications 23 Formwork is assembled to plans, specifications and class of surface finish , with support system set to correct height level and line The formwork removal process is after the concrete is casted and gained sufficient strength is called striking of formwork This will result in stresses in the structural element as due to loss of supports either on sides or below due to loss of support, it now becomes the responsibility of structure to support itself A properly hardened concrete element will be able to resist these

When To Remove Concrete Forms How Long Should Concrete Cure Before Removing Forms Deshuttering Time Civiconcepts

Slab Formwork Dokadek 30 Doka

FORMWORK Health and Safety Construction Safety Association of Ontario 21 Voyager Court South, Etobicoke, Ontario M9W 5M7 Canada (416) Fax (416) info@csaoorg wwwcsaoorg T_Con_Safety_TEXT 9/10/08 436 PM Page i Developed by trade labourmanagement health and safety committees, this manual is fully a document ofTo demonstrate competency, a candidate must meet the performance criteria of this unit by settingout and erecting suspended slab formwork for a slab size of a minimum of 10 square metres The formwork must incorporate one beam; Generally using OPC for Grade10 ,15 & Cement Concrete recommended time for removal of form work is For vetically supported form works in Beam, Columns & walls24 hrs Bottom supported formwork for Beams & Slabs min14 days Max21 days Upvote (0) Downvote (0) Reply (0) Answer added by hassan amer ali algaifi, مهندس مشروع , مؤسئسة علي الحصان للمقاولات 7 years

Concrete Floor Slab Construction Process Eplan House

Formwork For Civil Engineering Construction Works Ppt Video Online Download

Formwork

What Is Meant By Striking Formwork Removal Of Formwork Minimum Period Civildigital

Doc Floor Slab A O Academia Edu

Why Wouldn T You Use Modular Slab Formwork Systems

File Suspended Slab Formwork Jpg Wikimedia Commons

Cornerstone Building Civil Engineering Suspended Slab With Removable Formwork Ready For Concrete Pouring Looking At The Example In The Image The Steel Bars Are There To Withstand And Counteract The

Residential Extension Project Seven Hills

Suspended Concrete Floor Slab Formwork System

Geosky Geoplast

When To Remove Concrete Formwork Civilblog Org

Formwork Wikipedia

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

Concrete Formwork Suspended Slab Personal Protective Equipment Architect

Shuttering Removal Time Of Different Structural Members

How Many Days Can The Formwork Be Removed During Construction Bofu Formwork

Things To Check Before Concreting Beams Slabs

1

Method And Period Of Removing Formwork

Formwork For Civil Engineering Construction Works Dr V

Concrete Slab Wikiwand

Formwork Stripping Time Youtube

Expanded Polystyrene Eps Formwork Block Zlabform Zego Pty Ltd For Flooring Concrete Floor Slab Insulating

Architectural Aluminum Formwork System If Formwork System Kitsen Fastform

2

Column Formwork Procedure Formwork For Slabs And Beams

How When To Remove Formwork Hipages Com Au

Concrete Formwork Removal Time Specifications And Calculations The Constructor

What Is The Minimum Number Of Days To Dismantle Formwork In A Reinforced Concrete Slab Quora

Form Work Form Work Centring And Shuttering Form

Formwork Stripping In Progress Youtube

Slab Formwork Early Stripping Slab Formwork Systems Kitsen

4 3 Formwork For Concrete Stairs

Formwork Catalogue By Doka Issuu

3

Video Building Formwork

Formwork Removal Of Slab Embedded Beams Structural Engineering General Discussion Eng Tips

Concrete Formwork Removal Time Specifications Happho

Slab Formwork Destil Deck Farina Formworks Italy Formworks Props Scaff

Ring Lock Scaffolding Table Formwork Real Time Quotes Last Sale Prices Okorder Com

Formwork Cpccca3019a Erect Dismantle Formwork For Suspended Slabs Columns Beams And Walls Ppt Download

Safety Concrete Slab Aluminum Formwork Test

Suspended Slab Success Build It International

Concrete Slab Wikiwand

A Comprehensive Guide On Removing Formwork From Concrete Imc Grupo

/concreting-formwork-for-the-foundation-857756224-5b7ed9cdc9e77c00573a1357.jpg)

Safety Installation And Removal Of Formwork

Concrete Formwork Removal Time Specifications And Calculations The Constructor

Top Down Approach Braces Half Of Subgrade Construction Concrete Construction Magazine

Setup And Stripping

What Is Meant By Striking Formwork Removal Of Formwork Minimum Period Civildigital

How To Prevent Concrete Formwork From Failing

Safety Concrete Formwork For Suspended Slabs China Slab Formwork Aluminum Shutter Made In China Com

Scaffolding And Formwork Types Function And Difference

Concrete Formwork Removal Time Specifications Fantasticeng

De Shuttering Period Of Formwork Concrete Formwork Removal Time Youtube

Formwork For Civil Engineering Construction Works Dr V

Removal Of Formwork Know The Correct Time And The Precautions

Method Statement For Erection And Dismantling Of Slab Formwork Project Management 123

James Loder Construction Blog Site Visit Suspended Slabs And Suspended Ceilings

Formdeck Fd300 Durable Permanent Metal Tray Formwork Reinforcement System For Suspended Concrete Slab Construction

What Are Formwork Shuttering Centering Staging And Scaffolding

Frequently Asked Questions At First Floor Slabs

Formwork Wikipedia

Preventing Concrete Formwork Failures In The Commercial Construction Process

1

How Long Does It Take To Remove The Form After A Concrete Cast Of A Column And The Decking Of A House Quora

Ground Beam And Suspended Slab Formwork Work Process Traditional Timber Formwork Shuttering Works Youtube

China Table Formwork Will Be Quickly Removed By Shiftng Trolley In Slab Construction Slab Formwork System

Wall Formwork

Formwork For Decks And Floors Concrete Construction Magazine

Modular Formwork E Deck Paschal Werk G Maier Gmbh Slab Beam

2

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

Garagedeck The Flexible Formwork Solution For Beam Peri Usa Manualzz

Concrete Formwork For Slabs

Concrete Formwork Removal Time Specifications Happho

File Slab Formwork Tables Jpg Wikimedia Commons

How To De Shutter The Slab Of A High Rise Building

Stramit Condeck Hp

0 件のコメント:

コメントを投稿